Redid the flyers. The Knight torso is not that prominent anymore.

The exhausts got replaced by a proper tail fin.

The wings got smoother.

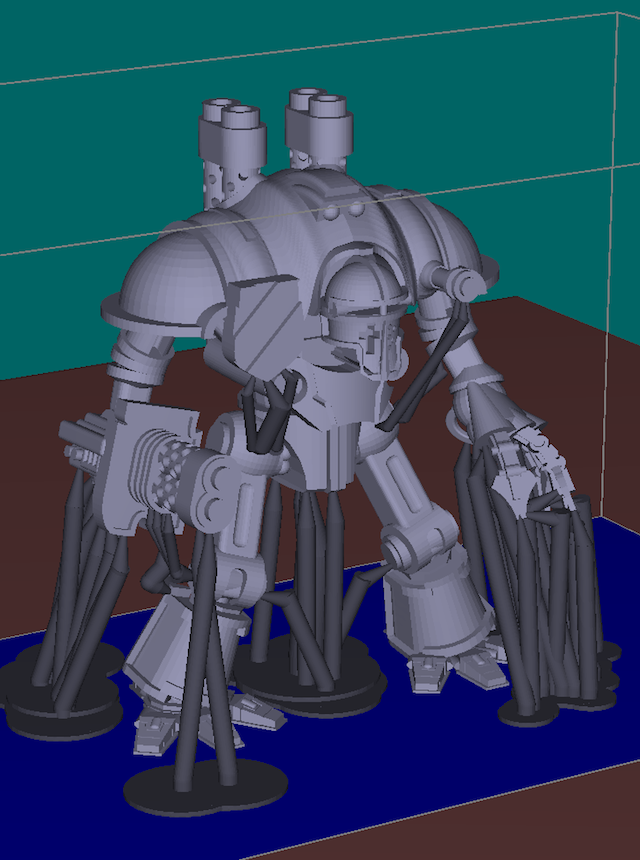

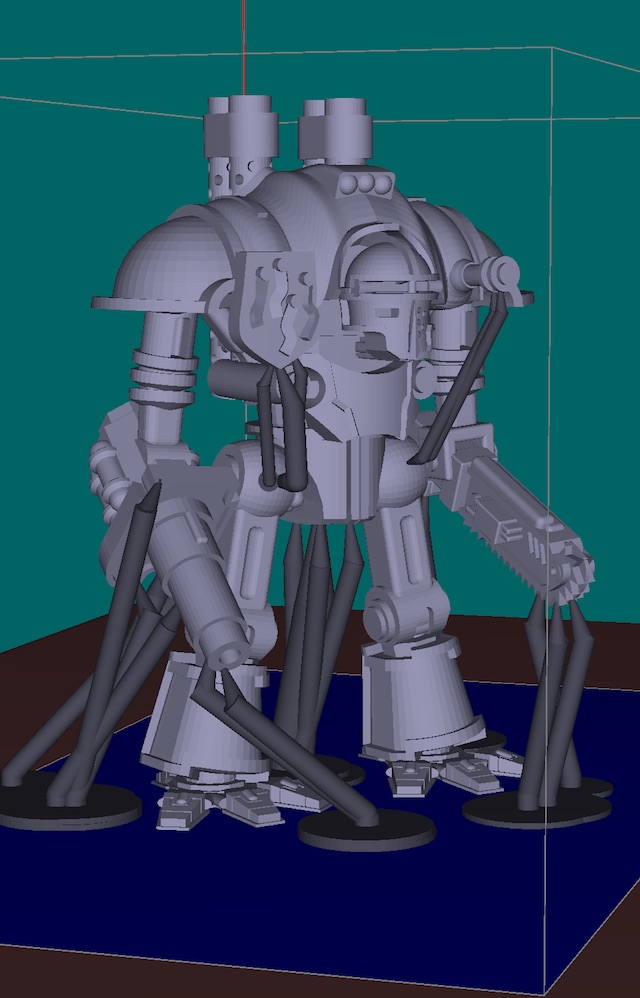

When you look at the model, you will realise that the side with the least detail is the back. And you can grow everything from the back to the front. So I printed it standing on it's back. This will give me the best quality for that model.

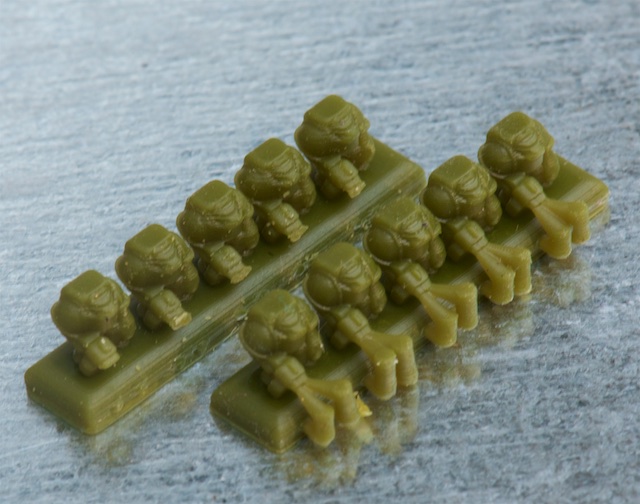

I used a multitude of very small supports (diameter 0.3mm). Those have the advantage that they can be broken off (nearly) without any damage to the model.

The drawback is that the model might break from the supports during the release cycle. To prevent this the model is placed so its "thin" side lies along the axis of vat movement.

In addition I added some thicker supports not for growing, but stability reasons. I choose the contact point of those, in a way that I can cut them easily off or any damage by breaking them off is hidden or could be part of a feature.

I also used a more heavily pigmented resin, which will give sharper detail and reduce light bleed - and can be photographed more easily.

Here you can see a wavy pattern, which shows that it is time to readjust and lube the printer. I usually only readjust when the waviness is still visible on the painted model.

Note the support inside the mounting hole for the stand.

Note the that the "stability" supports are mounted on some features(center of cross of lance) or accessible corners (tip of shield). This allows them to be broken of without to much "visual" damage or to be cut away easily.

@Toddermann

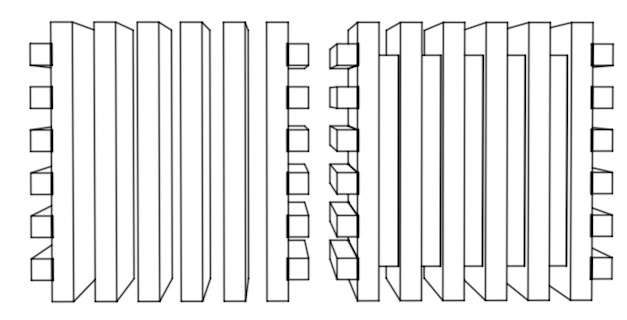

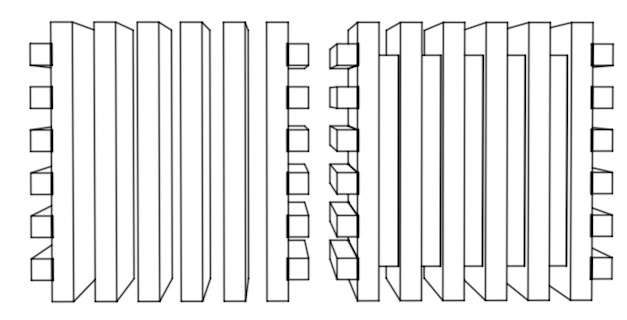

Is the radiator meant to be that way, i.e. separate fins without connection ?

If so it will never work without being fastened somewhere.

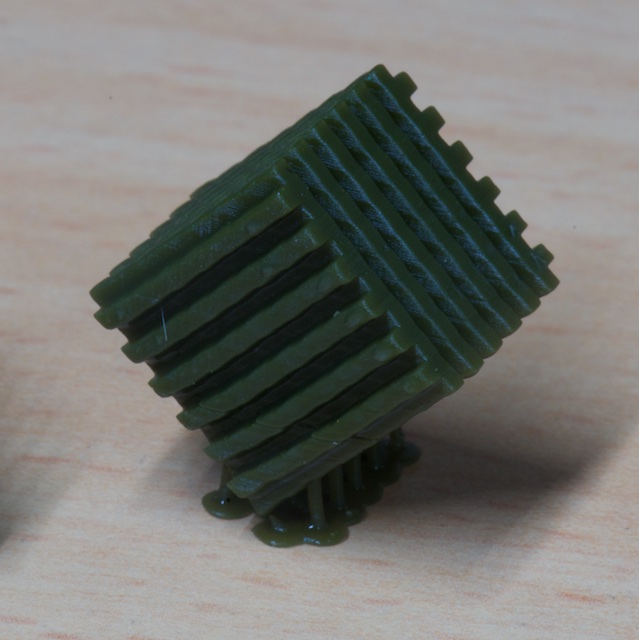

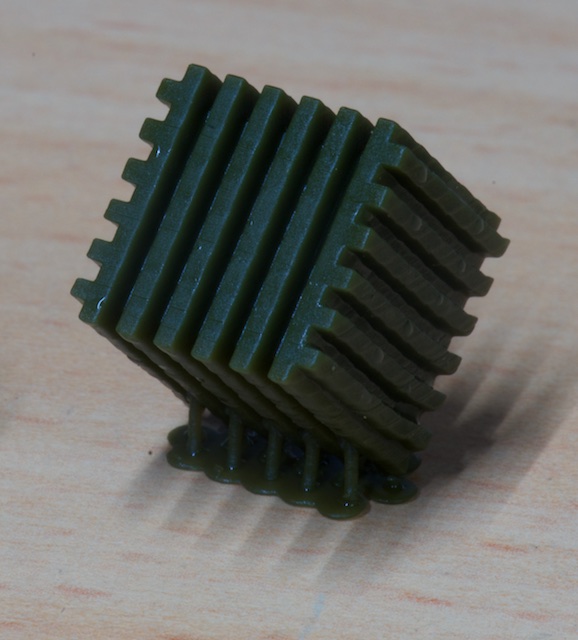

I added a "core" and will print a sample. I assumed 1 mm thickness for a fin. That's rather thick, but I do not know what resolution you use and what the radiator is meant for.

Here we go:

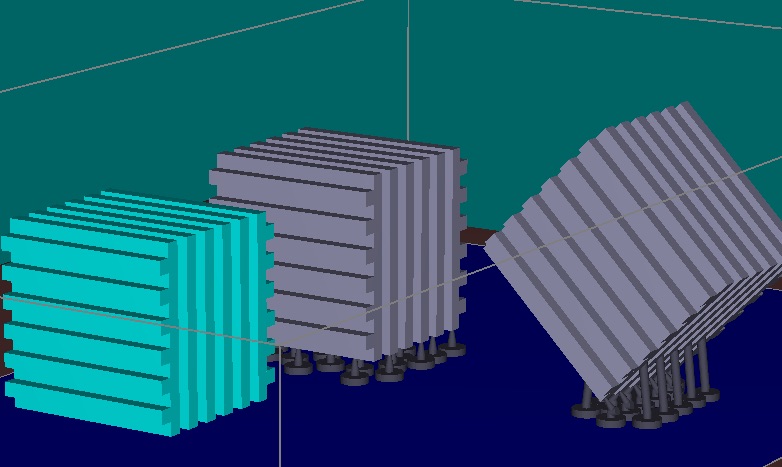

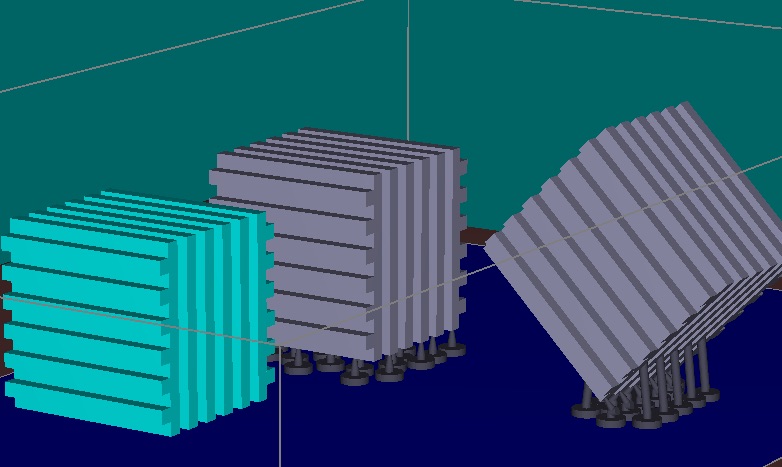

I did three Radiators. One on the build platform, one parallel to it, but on supports and one standing on an "edge".

Sadly the one parallel ripped off during printing and contaminated the on mounted on the build platform.

The one mounted on the ground looked quite ok, but basically it only left the on standing on na edge to judge.

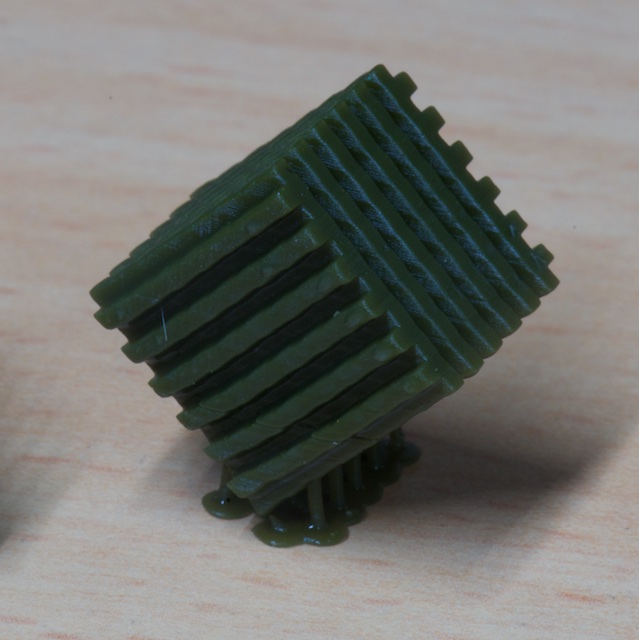

There is still some water on the model, I only saw it in the photograph.

On my monitor the model is 5 times as large as the real model. Keep that in mind, when judging quality.

Interestingly enough there seems to be some bend on the left end.

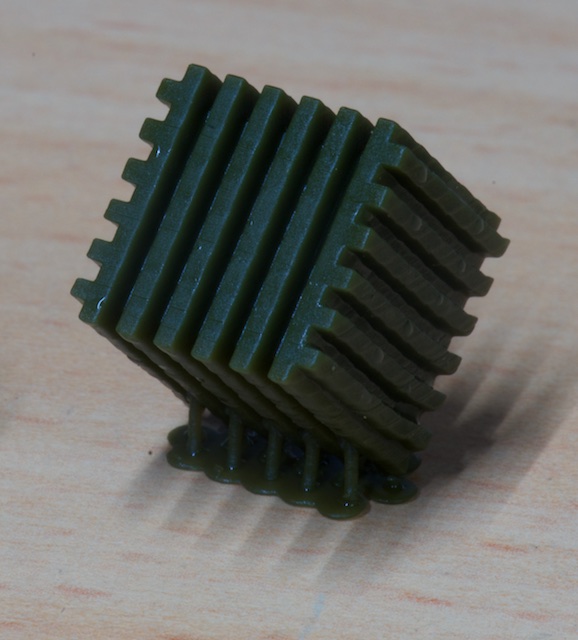

Now it moved to the right end - rotating does that to you.

Dust from removing the supports.

Basically I'd say it works. but needs some fine tuning (bends). It might be enough to rotate it relative to the vat movement. Or it might need another support to counter the bend.

You probably never get it it perfect with a "cheap" SLA printer, but I believe you can get it "good enough".

Having said that, there are definitely things best avoided in a design.

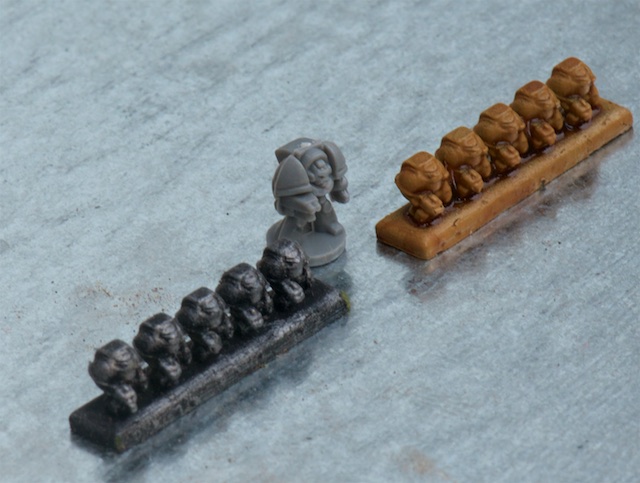

I think they look amazing, i actually really like the thingiverse design in a funny sort of way as it reminds me of the old first box set of space hulk minis.

I think they look amazing, i actually really like the thingiverse design in a funny sort of way as it reminds me of the old first box set of space hulk minis.